Many plastic parts contain specialised features such as snap hooks, mounting bosses and a gap at the joint where two components come together. Let see how we can do this inside SOLIDWORKS. There's a handy set of tools located in the menu, Insert > Fastening Features.

The model is first split into multiple bodies to identify the

upper and lower housing. The shell tool can be used to hollow out the part.

It will leave the faces you select open and create thin-walled features on the

remaining faces.

We will use the Lip/Groove

feature to create an edge. It is often used in plastic parts to prevent an

edge-to-edge joint between two parts.

Select the Lip/Groove

feature. Highlight the upper housing to receive the groove and the lower

housing to receive the lip.

For the Groove

Selection select the face and the edge you wish to apply. Repeat the same

procedure for the Lip Selection. You

can then define dimensions in the parameters.

Snap Hooks are common features in plastic parts enabling

quick assembly without the need for tools or fasteners.

First create sketch points where you wish locate the snap

hooks. Select Snap Hook feature,

pick the sketch point. Select a reference plane to define the vertical

direction of the snap hook. Select another reference plane to define the direction

of the hook (use Reverse direction if the hook is pointed the wrong way).

Define the dimensions in the Snap Hook

Data. Repeat the same procedure for each snap hook.

Next is to create the Snap Hook Groove. The dimensions of

the snap hook groove are driven by the snap hook. You can change the offsets

or clearances through the PropertyManager. Again, repeat the procedure for the

other snap hook.

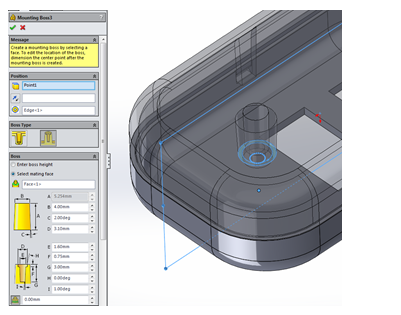

Mounting boss can be added for hardware fasteners. When

you create a mounting boss it can either be a through clearance hole for the

fastener or one with a blind hole for the threads.

First we will create the through clearance hole boss as

shown below. You can reposition the mounting boss by editing the 3D sketch.

Now that we have a clearance hole boss, it will be easier to

create the corresponding blind pilot hole boss because we can reference some of

the existing geometry to orient the boss and define its height.

To define the height, select the

mating face option and select the planar face on the mounting boss of the lower

housing.

For added support you can set the fin parameters. A reference plane can be used to orientate the fins. The number of fins will be equally spaced out.

No comments:

Post a Comment