As an applications engineer, I’m often asked by customers to

give advice on how to test designs using SOLIDWORKS. One of the most recent

examples that demonstrates how quick and easy SOLIDWORKS makes this process related

to testing how effective a layer of insulating material for an oven was.

The customer designs and manufactures insulation components

to be used in industrial ovens and wanted to assess how effective those

components were ate shielding the outer surfaces of the oven from the

temperatures achieved within.

SOLIDWORKS Simulation Professional gives you the ability to

run a Thermal analysis which can be carried out under a large range of

conditions and on complex model geometry. But without the lengthy operation of

setting up and running an analysis on a complex fully accurate model, here’s a

tip on running that all important first test to see if the components and the

material properties meet some basic criteria.

Firstly, simplify the study by only including what you have

to for the moment.

I have done this by only including what I am interested in

with regards to heat transferring from the inside of the oven to the outside

face. This leaves me with as sandwich of materials representing the internal

wall of the oven, the layer of insulating material and then the outside skin of

the oven.

By reducing the information that you are including in any

simulation study, you will in turn reduce the complexity of the study and therefore

the time taken to mesh and run the study. Also, with less geometry to consider,

the mesh used to describe your study can be made from smaller elements.

The next step after generating a suitable model for your

study is to create the study (or mathematical model) itself.

If you haven’t already, make sure that your SOLIDWORKS

Simulation add-in is turned on by going to Tools – Add-ins.

SOLIDWORKS Simulation is fully integrated into the user

interface enabling you to dynamically move between modelling and simulation

without skipping a beat.

On the Simulation tab on the command manager simply choose

to create a new study and select the type of study that you would like to

perform. Depending on the level of Simulation package that you have, only the study types available to you will be shown

at this point. For this example, I would like to perform a Thermal study.

A study tree is generated in the feature tree / property

manager area of the user interface and this allows you to keep track of and

modify your study. To speed things up even further, most functionality for

controlling and running your study can now be accessed by right-clicking the

relevant item in the study tree.

All of my materials have been transferred over from my

SOLIDWORKS model including the customer material properties that I have added

for my insulation material. Also because my basic layers of material are all

coincident, they will automatically have a bonded connection defined in the

study.

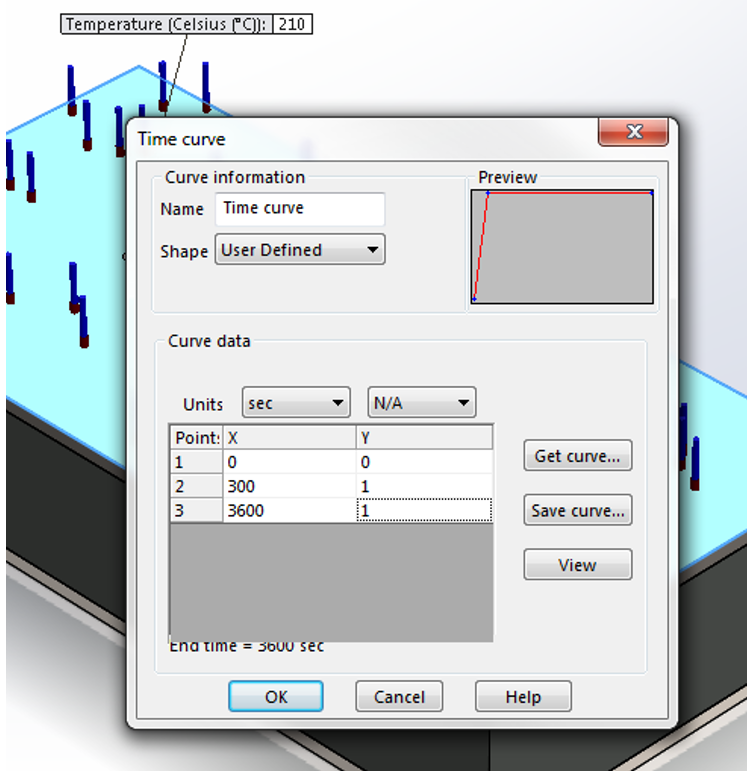

For this particular study, I would like to test the oven

when it is running at a temperature of 210 degrees Celsius over the period of

an hour and it will probably take a few minutes to heat up. SOLIDWORKS

Simulation Professional gives you the option to change the properties of the

study to make it transient and to specify both the overall time and the

increments to be tested by right clicking the study and choosing properties.

I've chosen to run the study for 3600 seconds at 60 second

increments.

Now what I need to do is apply the variables to my study. By

right-clicking the Thermal Loads section of the study tree, I get the options

to add Temperature, Convection, Heat Flux & Power, or Radiation values.

To start, I would like to define what temperature the

components are at the moment. To do this, I’ll create a temperature load as an

initial value for all solid bodies of 25 degrees Celsius.

Here I can set the time that the temperature source takes to

reach particular values. I’ll set this to reach full temperature at 300 seconds

(5 minutes).

One last thing before I run the study, I’ll specify that the

outer face of the oven is subject to convection into the surrounding

atmosphere. This is applied as a Thermal Load onto the outside face.

I’ll select the correct face and then add my Convection

Coefficient and Bulk Ambient Temperature. A Coefficient of 5-25 W/m^2.K will

represent natural convection into the surrounding atmosphere (i.e. no

assistance). So a value of 20 should represent a well-ventilated area. You can

also switch unit settings if it is easier for you, but 298.15 Kelvin works out

at 25 degrees Celsius.

At this point you can specify any mesh size that you would

like. But for this study I will simply use the default mesh size that

SOLIDWORKS Simulation generates based upon the physical geometry. To save

myself a couple of clicks, I can use the default mesh and run the study at the

same time by right clicking the top of the study tree and selecting Run.

Due to the simplified model geometry and using lightning

fast solvers, this study takes no time at all to solve.

I can analyse these results using a range of tools including Probe which is accessed through right-clicking the result plot. This enables me to analyse the results on just the face representing the outside of the oven and I can see that the temperature is reasonably low compared to the inside of the oven and I can check this information against my design requirements.

No comments:

Post a Comment