Keep following our SOLIDWORKS blogs on our website at http://www.tms-scotland.co.uk/Articles/SolidWorks

Friday, 6 May 2016

Monday, 2 February 2015

Fasten your Design!

You've created some plastic parts and are now unsure how they will fasten together. Maybe this blog will help.

Many plastic parts contain specialised features such as snap hooks, mounting bosses and a gap at the joint where two components come together. Let see how we can do this inside SOLIDWORKS. There's a handy set of tools located in the menu, Insert > Fastening Features.

For added support you can set the fin parameters. A reference plane can be used to orientate the fins. The number of fins will be equally spaced out.

Many plastic parts contain specialised features such as snap hooks, mounting bosses and a gap at the joint where two components come together. Let see how we can do this inside SOLIDWORKS. There's a handy set of tools located in the menu, Insert > Fastening Features.

The model is first split into multiple bodies to identify the

upper and lower housing. The shell tool can be used to hollow out the part.

It will leave the faces you select open and create thin-walled features on the

remaining faces.

We will use the Lip/Groove

feature to create an edge. It is often used in plastic parts to prevent an

edge-to-edge joint between two parts.

Select the Lip/Groove

feature. Highlight the upper housing to receive the groove and the lower

housing to receive the lip.

For the Groove

Selection select the face and the edge you wish to apply. Repeat the same

procedure for the Lip Selection. You

can then define dimensions in the parameters.

Snap Hooks are common features in plastic parts enabling

quick assembly without the need for tools or fasteners.

First create sketch points where you wish locate the snap

hooks. Select Snap Hook feature,

pick the sketch point. Select a reference plane to define the vertical

direction of the snap hook. Select another reference plane to define the direction

of the hook (use Reverse direction if the hook is pointed the wrong way).

Define the dimensions in the Snap Hook

Data. Repeat the same procedure for each snap hook.

Next is to create the Snap Hook Groove. The dimensions of

the snap hook groove are driven by the snap hook. You can change the offsets

or clearances through the PropertyManager. Again, repeat the procedure for the

other snap hook.

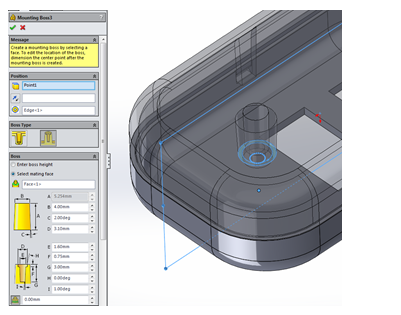

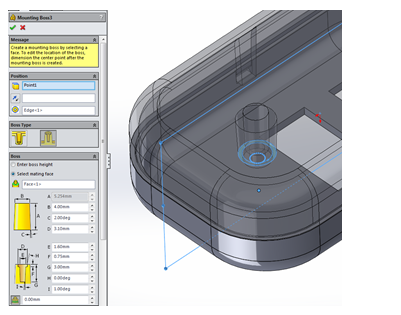

Mounting boss can be added for hardware fasteners. When

you create a mounting boss it can either be a through clearance hole for the

fastener or one with a blind hole for the threads.

First we will create the through clearance hole boss as

shown below. You can reposition the mounting boss by editing the 3D sketch.

Now that we have a clearance hole boss, it will be easier to

create the corresponding blind pilot hole boss because we can reference some of

the existing geometry to orient the boss and define its height.

To define the height, select the

mating face option and select the planar face on the mounting boss of the lower

housing.

For added support you can set the fin parameters. A reference plane can be used to orientate the fins. The number of fins will be equally spaced out.

Thursday, 15 January 2015

SOLIDWORKS World 2015

In

a world where design engineers thirst for knowledge…there’s SOLIDWORKS World!

Watch the #SWW15 trailer:

Wednesday, 10 December 2014

Using a Shell Mesh with Thin Components

I’ve always been clumsy when decorating my Christmas tree,

consistently working my way through my decorations at a rate of two to three

baubles per year. This inconvenience of

having to replace broken baubles has taken its toll and I’ve decided to design

the world first structurally sound bauble.

How can SOLIDWORKS Simulation help? Well stage one will be

to determine how much force one of these baubles will withstand before

breaking, that way we will have a basis for comparison. In order to do this we’ll set up a simple

stress test to begin with, with a fixture to simulate my hand holding the top

of the bauble and a force to represent the moment when I idly bump it into

something and turn another shiny ornament to a glittery mess on the floor. This is where I face problem one:

In order to achieve accurate results, it is recommended to

have at least two high quality mesh elements across the thickness of your part,

with our wall thickness of 1mm we therefore require an element size of

0.5mm. This would result in an

incredibly dense mesh across the surfaces of the model, which in turn would take

an unreasonable amount of time to both mesh and solve for a part of this

simplicity.

We can therefore use an alternate mesh type for thinned

walled parts (such as our bauble) known as a shell mesh. By utilizing a shell mesh, it is possible to

drastically reduce the mesh complexity resulting in significantly faster solve

times in models which feature a thin cross section.

To define your thin walled solid bodies as shell’s follow

this process:

Step 1: Right

click your chosen body in the Simulation tree and select ‘Define Shell by

Selected Faces’

Step 2: Select

the faces you would like to define as a shell.

Also input the thickness of your material as well as the material offset

to determine where the top and bottom faces lie.

Step 3: Re-mesh

your model to create your shell mesh.

Ensure you remove any small element size you may have added trying to

achieve two solid elements across the material thickness as these are not

necessary for a shell mesh. Once meshed

you will notice both the ‘inside’ faces and ‘outside’ faces are highlighted in

different colours, ensure the ‘outside’ and ‘inside’ colour is consistent and

doesn’t swap between faces.

If you have a mismatch of shell colour select the face,

right click the mesh in the simulation tree and choose to ‘Flip Shell Elements’

Step 4: Run your

simulation and get your results in a fraction of the time it would have taken

using Solid Elements.

Whilst I continue my design quest of the unbreakable bauble (You

hear it here first…) why not give shell elements a try for yourself and see how

this technique could save you analysis time.

Merry Christmas from everyone at TMS CADCentre!

Thursday, 13 November 2014

Subscribe to:

Posts (Atom)